Boiler pressure loss is a common issue that can disrupt heating and hot water supply in homes. According to experts, the most frequent causes include system leaks, recently bled radiators, or faulty components such as pressure relief valves, with each requiring specific troubleshooting steps to resolve. in this article we check why boiler keeps losing pressure.

Persistent boiler pressure loss can be frustrating and indicative of underlying issues in your heating system. Here’s a quick overview of common reasons why your boiler might keep losing pressure and potential solutions:

| Cause | Solution |

|---|---|

| System leaks | Inspect pipes, radiators, and valves for visible leaks; call a professional for hidden leaks |

| Faulty expansion vessel | Have a Gas Safe engineer check and potentially replace the expansion vessel |

| Malfunctioning pressure relief valve | Professional inspection and replacement if necessary |

| Air in the system | Bleed radiators and repressurise the system |

| Corroded or damaged components | Schedule a professional inspection and potential component replacement |

Identifying Boiler Leak Sources

Identifying the source of a boiler leak is crucial for effective repairs and preventing further damage. Common leak locations include loose pipe connections, faulty seals, and damaged components like the heat exchanger or pressure relief valve. Visual inspection is key – look for water pooling around the boiler, damp spots on floors or walls, and listen for unusual sounds like hissing or bubbling. For less obvious leaks, monitor the boiler’s pressure gauge; a consistent drop in pressure often indicates a hidden leak. If the leak source remains elusive, a qualified heating engineer can use specialized equipment like thermal imaging cameras or moisture meters to pinpoint the problem.

Impact of Faulty Pressure Valves

Faulty pressure relief valves can have significant impacts on boiler systems and home safety. A malfunctioning valve may fail to release excess pressure, potentially leading to dangerous overpressure situations or even explosions in extreme cases. Conversely, a valve that releases pressure prematurely can cause frequent pressure drops, resulting in inefficient heating and increased energy consumption.Key impacts of faulty pressure valves include:

- Safety hazards due to potential overpressure

- Reduced boiler efficiency and higher energy bills

- Inconsistent heating performance and comfort issues

- Water damage from leaks or valve discharge

- Increased wear on other boiler components

- Higher repair costs if issues are left unaddressed

Regular inspection and maintenance of pressure relief valves is crucial to prevent these problems and ensure safe, efficient boiler operation.

Role of Expansion Vessel Issues

Expansion vessel issues play a significant role in boiler pressure problems. The expansion vessel, a crucial component in sealed heating systems, absorbs excess water volume as it expands due to heating, preventing pressure buildup . When faulty, it can lead to pressure loss without visible leaks.Key points about expansion vessel issues:

- A damaged internal diaphragm can cause water logging or loss of air pressure

- Faulty vessels may result in pressure exceeding 3 bar during heating, triggering the pressure relief valve

- Symptoms include inconsistent heating, excessive noise, and frequent pressure drops

- Regular maintenance, including recharging the vessel to the correct pressure (typically 0.8-1.5 bar), is essential

- If the vessel fails to hold pressure after recharging, replacement may be necessary

Addressing expansion vessel problems promptly can prevent further damage to the boiler system and ensure efficient operation.

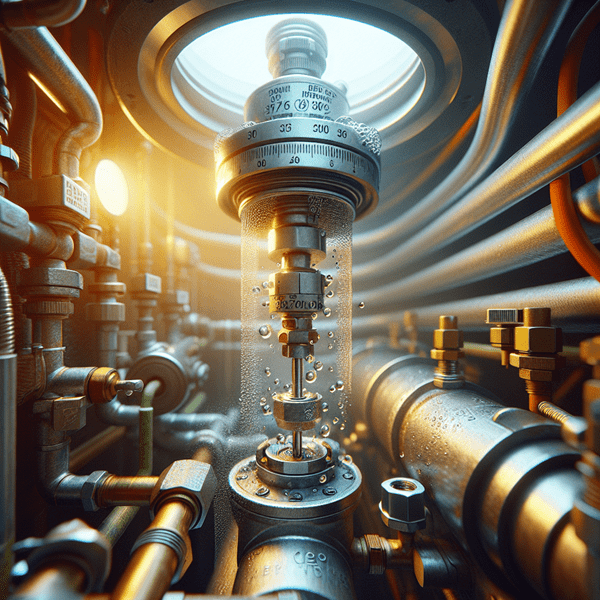

Boiler Pressure Valve

Boiler pressure relief valves are critical safety components that protect heating systems from dangerous overpressure situations. Here’s an overview of how these valves function and their importance:

- Automatically open when pressure exceeds a preset limit (typically 30 psi for residential boilers)

- Release excess pressure by discharging water through a discharge pipe

- Close again once pressure returns to a safe level

- Prevent potential boiler explosions or system damage from overpressure

- Usually spring-loaded, with the spring calibrated to the specific pressure rating

- Require regular maintenance and testing to ensure proper operation

- Can stay in service for up to 30 years if properly maintained

- May indicate other system issues if frequently activating

Regular inspection of the pressure relief valve is crucial for boiler safety and efficiency. If the valve shows signs of leaking, sticking, or failing to operate correctly, it should be inspected and potentially replaced by a qualified technician.